Well, a boiler is equipment used to convert liquid into high-pressure vapor. It is familiarly known as the famous equipment "steam boiler", that produces steam from water. However, a reboiler does the same operation, due to its involvement in the continuous process of boiling the recycling liquid stream in its shell side. The name was given by the reason for boiling the same liquid again and again. In most cases, the liquid is boiled in a shell with the help of hot pipes (tubes). On the external surface of the tubes, liquid changes its phase by observing heat (latent heat + sensible heat). In turn, the required high temperature of the hot tubes is maintained by circulating low-pressure or high-pressure steam inside the tubes. Based on the temperature sensitivity of the material and rate of vapour formation boiling is done inside or outside of the tubes.

Types of reboilers:

- Kettle reboiler (natural-circulation)

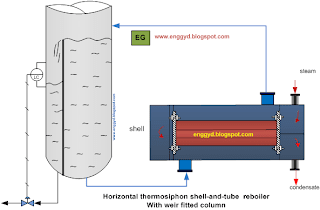

- Thermosiphon reboiler (natural-circulation, operates based on the head of liquid) Calculators

- Vertical model

- Horizontal model

- Forced circulation type (liquid is pumped into the shell)

Applications:

Used as heating equipment for distillation column (generates vapors for the bottom tray like Glycol reboiler, Amine reboiler, etc).Steam production using hot process streams.

Reboiler design aspects:

Designing a shell-type reboiler for the required process conditions involves making a decision about the basic options before starting the design calculations. An engineer with his experience can choose the type of flow in and outside of the tube, using plain or finned-type tubes during the primary selection of the model. He even considers the reboiler cleaning frequency, and how to minimize the startup time. Nucleate pool boiling data, knowledge of two-phase flow theory, and heat transfer coefficients are some of the important information required for designing.

To improve the performance of heat transfer rate, low-temperature approach enhanced boiling tubes are used in new models which benefits the industrial economy.

To improve the performance of heat transfer rate, low-temperature approach enhanced boiling tubes are used in new models which benefits the industrial economy.

Variables that influence the reboiler design are:

- Pressure drop (pressure gradient)

- Mass velocity

- Flow pattern (parallel, cross, counter types)

- Tubes orientation (vertical or horizontal)

- Critical heat flux condition

- Thermal hydraulics

- Reboiler duty

Heating medium used in most reboilers:

- Low-pressure to high-pressure steam

- Commercial heat-transfer fluids (Dowtherm oil)

- Hot process streams

Thermosiphon type reboiler has similar operation procedures to a single effect evaporator and a calandria. Its working principle resembles the manometer model. The liquid head in the vessel of a still/distillation column or separator maintains the flow rate of the liquid into the reboiler.

Variables that affect the operation of thermosiphon reboilers are:

- Variation of temperature difference

- Operating pressure

- Liquid head

- Length and diameter of the pipes

- Using a flow control valve in the bottom of the product liquid outlet pipeline.

- Fitting a weir inside the reboiler or in the column so that it allows only the overflow to its outlet pipe.

- Adjusting the steam or hot medium inlet flow rate based on vapor temperature.

- Independent flow control of stem inlet into the reboiler.

- Cascade control of both temperature of vapor and flowrate of steam