A catalyst will change or influence or effect three major parameters which are:

1. The rate of a reaction

2. The energy required for a chemical reaction

3. The sequence of mechanism steps of a chemical reaction

However, it does not change the equilibrium of the reaction. Bulk production of the chemical will depend on the choice of catalysts for example,

The catalyst for water shift reactions:

The catalyst for Hydrogenation reactions:

Absorbent

Every petroleum product has impurities, toxic or poisonous material where sulphur is one of them, which is present in higher percentage above all other, so for removing sulphur content, which may be in the form of hydrogen sulphide trace, are mostly absorbed on solid surface after maximum removal in pretreatments operations, for absorption process a Zinc oxide is used as absorbent, it made into cylindrical shaped extrude which is used to absorb Hydrogen Sulphide into its small pores, and the dimensions of the cylinder would be about 4mm diameter and 8 mm height.

The catalyst used for Methanation process:

CO + 3H2 → CH4 + H2O Δ H = -49.2Kcal/mol

CO2 + 4H2 → CH4 + 2H2O Δ H = -39.4Kcal/mol

The catalyst used in the Reforming process:

And another type of platinum-on-alumina based catalyst which has the same shape but different dimensions which are 20 mm outer diameter and 18 mm height with each hole diameter 4 mm, its lifetime is greater than 10 years.

1. The rate of a reaction

2. The energy required for a chemical reaction

3. The sequence of mechanism steps of a chemical reaction

However, it does not change the equilibrium of the reaction. Bulk production of the chemical will depend on the choice of catalysts for example,

- Raney Nickel: used in the hydrogenation of vegetable and animal oils

- Platinum-on-alumina: Reforming of petroleum naphtha

- Promoted Iron: Ammonia synthesis

|

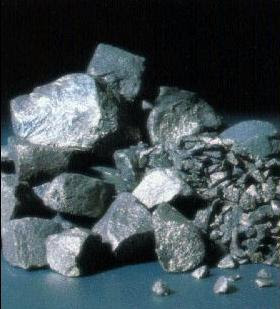

| Iron Catalyst |

The iron-based catalyst which is mostly used for ammonia synthesis reaction of Nitrogen and Hydrogen reactants, its optimum dimensions are about 1.5 to 3 mm diameter and have lifetime form 5 to 10 years

The catalyst for water shift reactions:

For high-temperature shift conversion reaction where Carbon dioxide is produced from Carbon monoxide on the catalyst of Iron /Chromia which has the optimum shape of tablets and has dimensions with diameter 6 mm and height 6 mm, it lifetimes can be expected greater than 5 years.

|

| Iron -Chromia base Catalyst |

For further reducing carbon-monoxide and thereby increase the H2 yield for Ammonia synthesis. The Low-Temperature shift catalyst is a combination of copper and zinc oxide and is active at a lower temperature where restriction in conversion due to equilibrium are minimized. But LT shift catalyst is very sensitive to high temperature, poisoning and contamination by water. It is made as tablets shape and has dimensions of 4.3mm diameter and 3.2mm height, with a lifetime expected to more than 5 years.

|

| Copper Based Catalyst |

The catalyst for Hydrogenation reactions:

In most hydrogenation reactor where hydrogen will be reacted with the reactant on a catalyst made from Nickel- Molybdate and its shape are designed as ring structure having dimensions, 5 mm outer diameter and 2.5 mm inner diameter, about greater than five years of life is expected in the production services.

|

| Zinc Oxide Pellets |

Absorbent

|

| Nickel- Molybdate Catalyst |

|

| Nickel-based Catalyst |

The process gas composition contains small traces of CO and CO2. Removal of carbon oxide is accomplished in a methanator where CO + CO2 are converted in the presence of nickel-based catalyst into CH4. The shape of the nickel-based catalyst is made in a rings formation having dimensions of about 5 mm outer diameter its lifetime is expected to be about more than 10 years

CO + 3H2 → CH4 + H2O Δ H = -49.2Kcal/mol

CO2 + 4H2 → CH4 + 2H2O Δ H = -39.4Kcal/mol

The temperature rise for one percent of CO converted is 74oC and for one percent of CO2 converted, it is 60oC.The performance of methanator where catalyst Rx takes place is directly related to the efficiency of co-conversion and CO2 removal sections. High concentrations of carbon oxides can cause temperature runaway in the methanator catalyst and it is necessary to protect both the reactor vessel and the catalyst from serious damage. The vessel should be isolated, depressurized and purged with nitrogen. At a temperature below 204oC Nickel in presence of CO forms nickel carbonyl which is very poisonous.

|

| Nickel-based Catalyst type I |

The catalyst used in the Reforming process:

In reforming process where mostly high chain hydrocarbon can be reformed or rearranged for the desired products, this reaction becomes a primary step in the most petrochemical process plants the best catalyst used for this is a Nickel based catalyst with a cylindrical shape having seven holes with dimension having 16mm outer diameter and 11 mm height and each hole is of 3.5mm diameter, when coming to its lifetime it would about in the range 3 to 5 years.

|

| Nickel-based Catalyst type II |

These catalysts can be made from natural and synthetic materials, such as most widely used natural catalyst is clay and Zeolites whereas crystalline aluminosilicates are an example of the synthetically prepared catalyst. This is what a catalyst used and prepared.